Understanding the Applications of Vacuum Forming in Molding

Exploring the Uses of a Key Manufacturing Technique

Understanding the applications of vacuum forming in molding is essential for those interested in modern manufacturing processes. This technique is widely used to create a variety of products with precision and efficiency. By applying heat and pressure, materials are molded into desired shapes, making them ideal for numerous industries.

The Basics of Vacuum Forming

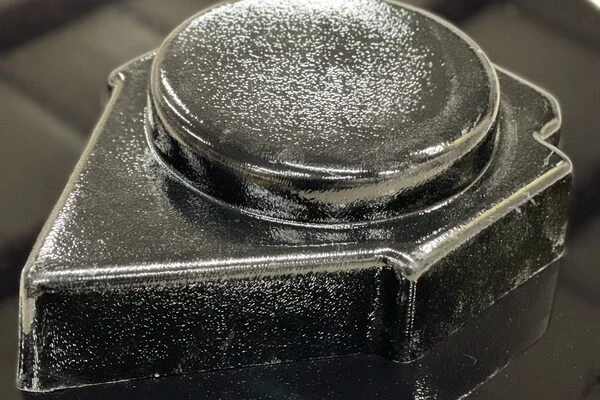

Vacuum molding is a popular method used for shaping plastic sheets. It starts by heating a plastic sheet until it’s pliable and then stretching it onto a mold. The vacuum then sucks out the air between the mold and the sheet, forming a tight fit around the design. This process allows manufacturers to produce detailed components quickly and cost-effectively.

- The automotive industry uses it for dashboard covers.

- Packaging solutions often rely on this method for custom packaging trays.

- The medical field utilizes it for creating equipment housing.

- Retail displays frequently incorporate parts made through this technique.

Diverse Industrial Applications

Industries across the board have discovered the benefits of vacuum molding. Its flexibility makes it suitable for small-scale prototyping as well as large-scale production. In addition to the automotive and medical sectors, home appliance manufacturing also leverages this method for constructing components like refrigerator linings and washing machine panels.

Sustainability and Efficiency

The sustainability aspect of vacuum molding should not be overlooked. This process reduces waste significantly because excess material can often be recycled or reused in future projects. Moreover, it requires less energy compared to other molding techniques. These factors make it an environmentally friendly option while maintaining high production standards.

Custom Solutions With Vacuum Forming

One of the greatest advantages of vacuum forming is its ability to produce custom solutions tailored to specific needs. Since molds can be designed to exact specifications, companies can create unique parts that align perfectly with their product requirements. This capability is especially beneficial for startups and small businesses looking to innovate without incurring massive costs.

Your Partner in Innovation

D&D Plastics stands ready to assist you with state-of-the-art techniques tailored to your business needs. Reach out today at (801) 373-0202 to explore how we can support your next project with unparalleled expertise in vacuum molding solutions in Orem, UT or the surrounding areas.