Key Differences Between Vacuum Forming and Injection Molding

Understanding the Variations in Manufacturing Techniques

The key differences between vacuum forming and injection molding lie primarily in their processes, applications, and material usage. Each method offers unique advantages, making them suitable for different industrial needs. Understanding these distinctions can help businesses choose the right technique for their manufacturing projects.

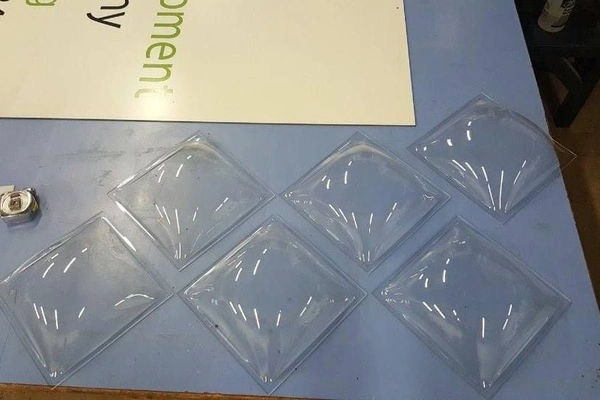

The Basics of Vacuum Forming

Vacuum forming is a popular manufacturing process often used to create lightweight and durable components. It involves heating a plastic sheet until it becomes pliable, then using a vacuum to form it over a mold. This technique is particularly beneficial for producing large parts with simple designs at a lower cost.

- Cost-effective for low-volume production

- Ideal for creating prototypes and custom parts

- Faster turnaround time compared to other methods

- Suitable for large-scale components

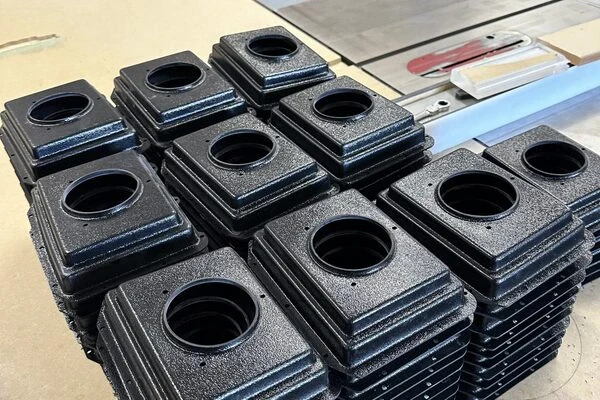

The Intricacies of Injection Molding

Injection molding, on the other hand, is known for its precision and ability to produce complex parts. In this process, melted plastic is injected into a mold cavity where it cools and hardens. It’s a preferred choice for high-volume production due to its speed and consistency. Manufacturers benefit from reduced labor costs and high-quality finishes.

Comparing Material Usage

Material selection differs significantly between the two methods. Vacuum molding typically uses thermoplastics that are easy to shape when heated. Common materials include acrylic, polycarbonate, and polyethylene. Injection molding accommodates a broader range of plastics and allows for the integration of additional materials like metal inserts or glass fibers, enhancing product durability.

Choosing the Right Manufacturing Process

When deciding between these techniques, consider factors such as project size, complexity, budget, and production volume. Vacuum molding is advantageous for projects requiring rapid prototyping or small batches. Conversely, injection molding is ideal for mass production where detail and uniformity are crucial.

Explore Further Manufacturing Insights

Orem, UT offers various opportunities to explore different manufacturing technologies. Our team at D&D Plastics is ready to guide you in selecting the appropriate method for your project needs. Reach out to us at (801) 373-0202 today to learn more about our services.